How Neat Helps Distributed APAC Teams with Smarter Video Tech

Christina Tan, Jan 8, 2026

Neat brings a new level of clarity to distributed APAC manufacturing teams with AI-driven audio and video built for fast, accurate, decisive collaboration. When Neat devices are on the factory floor, teams can instantly see, hear and understand what’s happening—no matter how far apart they are.

Manufacturing across the Asia-Pacific region is entering a new era. Production is expanding into emerging markets, supply chains are stretching across borders, and factories are becoming more digital, automated, and data-driven. Yet even as technology advances, many teams still struggle with a very human challenge: understanding what’s happening on the factory floor when they’re not physically there.

In a region this interconnected, clarity is more than a nice-to-have—it’s an operational advantage. The ability to see, hear, and understand a situation in real time, no matter the location, is becoming essential to keeping work flowing.

A region moving into its next manufacturing chapter

Asia-Pacific’s momentum reflects this need. The World Bank’s East Asia & Pacific Global Economics Report 2025 highlights steady growth, fuelled by electronics, machinery, and the rise of AI-related production. At the same time, ASEAN+3—Southeast Asia together with China, Japan and South Korea—remains one of the world’s most deeply connected manufacturing ecosystems, strengthened by diversified supply chains and resilient investment, according to ASEAN+3’s 2025 report.

The result: a manufacturing landscape that’s broader, faster, and more distributed than at any point in the past decade.

An industrial landscape rich in strengths

APAC’s manufacturing power comes from its diversity.

- China leads in advanced manufacturing, robotics, batteries, and machinery.

- Japan continues to anchor precision engineering and industrial robotics.

- Taiwan sits at the centre of the global semiconductor and ICT hardware ecosystem, powering AI and high-performance computing.

- India is rapidly scaling across automotive, electronics, and industrial machinery.

- Vietnam has become a significant hub for electronics assembly and export manufacturing.

Surrounding these are fast-rising frontier markets:

- Indonesia is becoming critical to the EV battery supply chain.

- Malaysia strengthens its role in semiconductor assembly and testing.

- Thailand continues to lead in automotive and EV manufacturing.

- The Philippines grows in EMS and aerospace components.

- Bangladesh remains a global force in textiles and labour-intensive production.

Manufacturing in APAC is no longer centred around a handful of countries—it’s a connected web of factories, suppliers, engineers, and partners operating across borders and time zones.

Where collaboration still slows the region down

Despite the sophistication of this ecosystem, collaboration often remains surprisingly manual.

Teams still rely on shaky smartphone videos, voice-only troubleshooting and travel-heavy problem-solving. Training varies from site to site. Supplier-customer alignment can stall when information is unclear or incomplete.

A lack of technology doesn’t cause these issues—in many cases, factories have never been more advanced. They stem from a lack of clarity. When people can’t see what others are seeing:

- troubleshooting becomes guesswork

- decision-making slows

- downtime extends

- training drifts

- quality follows

- alignment with partners becomes harder

In distributed operations, uncertainty quickly becomes expensive.

Intelligence that brings clarity to every site

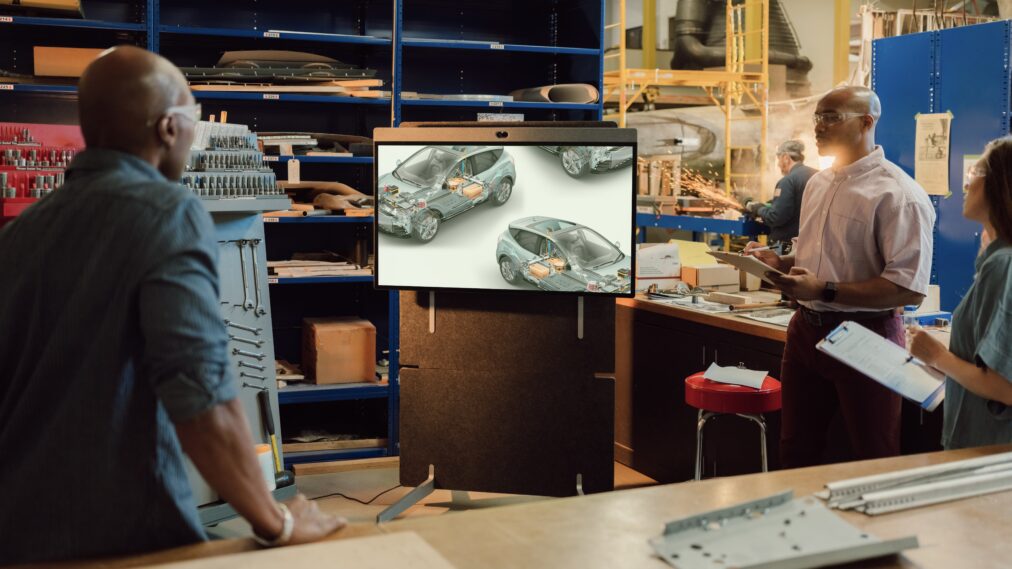

This need for shared clarity is where intelligent video collaboration is reshaping how manufacturing teams operate across borders. Instead of keeping teamwork confined to boardrooms or conference calls, factories are bringing clarity directly to the production line.

Imagine a line in Vietnam stopping unexpectedly while engineering sits in Taiwan, and a critical supplier is in southern China. With a Neat device on the factory floor, everyone sees the issue as if they’re standing beside the machine. AI framing follows operators naturally as they move. Noise reduction cuts through machinery. Engineers can zoom in on components, observe movements and troubleshoot together—turning what used to take days into a single focused session.

AI-powered bar and board devices

Training becomes consistent, too. A new standard operating procedure rolled out across Indonesia, Thailand, and the Philippines often results in subtle variations. Neat’s AI-powered bar and board devices, with their innovative audio and video capabilities, ensure every site sees the same demonstration with the same clarity—hands, tools, and materials are visible even in challenging factory environments.

Supplier relationships improve when measurements or processes can be reviewed in real time. Commissioning new lines speeds up when experts guide technicians remotely. Even customer audits run more smoothly when teams can provide transparent virtual walkthroughs rather than travelling to actual factory locations.

A quiet advantage with real impact

These moments add up, and by 2026, the APAC manufacturers pulling ahead will be those that can:

- fix issues fast across borders

- train consistently at scale

- cut downtime

- synchronise multi-site operations

- align quickly with partners

- grow without more travel

When they do, the results follow: lower costs, tighter quality, stronger trust, faster delivery and more resilient operations—the essentials of winning in a distributed manufacturing world.

Innovation, efficiency, and strategic adaptation

As manufacturing continues to expand across both established and emerging markets, the companies that stay ahead will be those that build clarity into how they work. Not just clearer communication, but clearer operations, decision-making and alignment across every plant, supplier, and partner.

Intelligent collaboration is no longer about better meetings. It’s becoming part of the production rhythm—helping teams see more, understand more and resolve issues faster, wherever they are. And it’s in these everyday moments of connection that Neat helps companies make the most meaningful difference, bringing innovation, efficiency, and strategic adaptation to companies across the APAC region.

Experience Neat’s intelligent, simple video devices in action during one of our live product tours or book a one-on-one demo with a Neat specialist for a personalized deep dive.